全自动一拖一口罩机

详情介绍

Full-automatic face mask making production line GC-19501

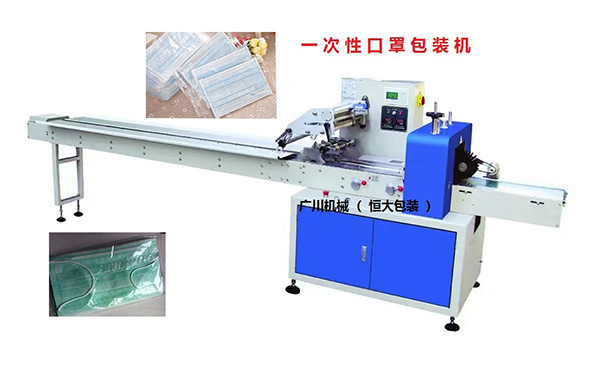

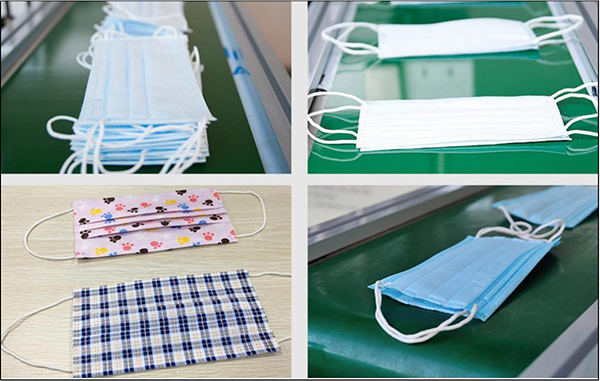

样品图片(Sample photos):

(优势)Advantage

1.全机采用铝合金结构,更加美观坚固

The whole machine adopts aluminum alloy structure, which is more beautiful and sturdy

2.高稳定性

High stability

3.全自动外耳带点焊机同时制作口罩片材和外部耳焊点焊部分,可节省劳动一旦无纺布原料在生产过程中使用完,机器可以自动停止。

Fully automatic outer ear spot welding machine produces masks sheet and outer ear welding spot welding part at the same time, which can save labor. Once the non-woven fabric material is used up in the production process, the machine will automatically stop.

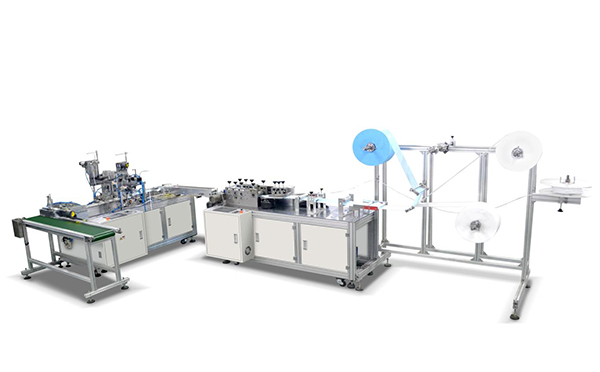

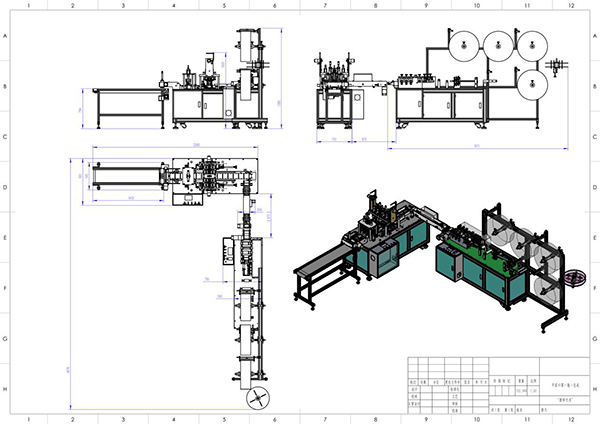

生产线结构(production line structure):

由一台主机(口罩成型机)加一台伺服型耳带焊接机(外耳带),通过传输线连接。可实现从卷料上料、折叠压合成型及分切、耳带上料机焊接、下料的全自动生产过程。

A host (masks forming machine) plus two ear band welding machines (outer ear bands) are connected by a one-to-one transmission line. It can achieve the full-automatic production process from coil feeding, folding and pressing, and slitting, ear band feeding machine welding, and unloading.

技术参数(Technical parameter):

机器型号 | GC-1950-1 |

产量 | 80-120 个/分钟 |

电压 | 220V/50hz |

机台尺寸 | 5300*3300*1700mm ((长*宽*高) |

口罩尺寸 | 17.5*9.5cm |

功率 | 11KW |

机器重量 | 1000Kg |

三层原材料报告(Three Tier raw material report):

序列号 | 熔喷布 | 无纺布 | 无纺布Non-woven | 鼻梁条 | 耳带 |

图片 |

|

|

|

|

|

规格 | (Width):17.5cm | (Width):17.5cm | (Width):19.5cm | (Width):3mm | (Width):2.5mm |

本体机配置单(Main machine configuration sheet):

一拖一全自动平面口罩生产线采用设计,只需将生产原材料装置于送料架上,完成调制后,机台实现自动生产,仅需要 1 名人员操作包装,完全实现全程自动化生产,设备采用超音波焊接方式,样式美观、卫生、环保。

产量为 80-120 片分钟,鼻梁条长度可调,产品尺寸误差为±1mm,根据需求更换部分模具即可实现多种规格的口罩片,本机台可生产各种无纺布口罩、光滑布口罩、纱布口罩、活性炭口罩,双鼻线口罩等。

1、The one-to-one full-automatic flat masks production line adopts advanced design. It only needs to place the raw materials on the feeding rack. After the modulation is completed, the machine can automatically produce. Only one person needed to operate the packaging, which fully realizes the entire automated production. The equipment adopts ultrasonic welding method, with beautiful appearance, sanitation and environmental protection

The output is 80-120 per minutes, the length of the nose bridge strip is adjustable, and the product size error is fluctuating to 1 millimetre. According to the needs of replacing some molds, a variety of masks sheets can be achieved. This machine can produce non-woven masks, smooth cloth masks, gauze masks, activated carbon masks, double nose line masks, etc.

2.配置单:Configuration list

序号 | 类型 | 品牌 | 备注 |

1 | 触摸屏 | 昆仑通泰 | |

2 | PLC | 西门子 | |

3 | 中间继电器 | 欧姆龙 | |

4 | 断路器 | 施耐德 | |

5 | 接触器 | 施耐德 | |

6 | 两位旋转按扭 | 施耐德 | |

7 | 点动按钮 | 施耐德 | |

8 | 点动按钮 | 施耐德 | |

9 | 点动按钮 | 施耐德 | |

10 | 急停按钮 | 施耐德 | |

11 | 变频器 | 施耐德 | |

12 | 散热风扇 | 中国 |

NO. | Name | Brand | Specification |

1 | touch screen | MCGS | |

2 | PLC | SIEMENS | |

3 | auxiliary relay | OMRON | |

4 | Circuit breaker | Schneider | |

5 | Contactor | Schneider | |

6 | Two Button rotary switch | Schneider | |

7 | Inching button | Schneider | |

8 | Inching button | Schneider | |

9 | Inching button | Schneider | |

10 | Scram button | Schneider | |

11 | Frequency transformer | Schneider | |

12 | Radiator fan | China |

序列号 | 产品名称 | 产品图片 | 机器优势 |

1 | 切割胶辐&牵引辊 |

| 我们用铭钢盖住橡胶根 两边,所以橡胶在长时 间使用后不会从侧面断裂。 |

2 | PLC触摸屏 |

| 西门子 PLC系统。 |

3 | 鼻梁条送入装置 |

| 我们使用鼻梁条直接送 入装置,它可以保证在 加工过程中,鼻梁条可 以更笔直的插入,所以 成品的口罩将是平整的 和美观的。 |

4 | 电控箱 |

| 我们使用的是西门子 |

5 | 马达 |

| 齿轮马达 |

6 | 风扇 |

| 我们将风扇安装在超声波喇叭附近,降低喇叭温度,延长超声波寿命。 |

7 | 超声波焊接系统 |

| 在口罩本体机中有1台 超声波系统。 |

伺服耳带点焊部分配置单: Servo Type Ear band welding machine

采用超音波焊接方式将松紧带熔合于口罩两端,仅需一名操作员将口罩本体一片片置放于口罩盘内,后续动作到成品完成由设备自动完成。本机采用伺服、步进驱动,传动,速度可调。

Ultrasonic welding method is adopted to fuse the elastic band to the inner side of both ends of the mask body, which is the last processing procedure of the inner ear mask production. Only one operator needs to place the mask body piece by piece in the mask plate, and the equipment will automatically complete the following actions until the finished product.

This machine adopts servo step drive,drive accurate, speed adjustable

Technical parameter

机器尺寸 | 2100*1000*1600mm |

电压 | AC 220V,50-60HZ |

产量 | 80-120 PCs/min |

功率 | 2.7KW |

配置单Configuration list

序号 | 类型 | 品牌 | 备注 |

1 | 触摸屏 | 昆仑通泰 | |

2 | PLC | 西门子 | |

3 | PLC扩展 | 西门子 | |

4 | 中间继电器 | 欧姆龙 | |

5 | 断路器 | 施耐德 | |

6 | 接触器 | 施耐德 | |

7 | 两位旋转按扭 | 施耐德 | |

8 | 点动按钮 | 施耐德 | |

9 | 点动按钮 | 施耐德 | |

10 | 点动按钮 | 施耐德 | |

11 | 急停按钮 | 施耐德 | |

12 | 开关电源 | 明纬 | |

13 | 散热风扇+方形防尘罩(灰色) | 中国 | |

14 | 伺服电机 | 三菱 | |

15 | 伺服电机驱动器 | 三菱 | |

16 | 气缸 | 亚德客 | |

17 | 超声波 | 中国 | |

18 | 电磁阀 | 台湾金器 | |

19 | 接近开关 | 欧姆龙 | |

20 | 光电开关 | 欧姆龙 | |

21 | 单相电机 | 松岗 | |

22 | 空气开关 | 施耐德 |

No. | Name | Brand | Specification |

1 | Touch Screen | MCGS | |

2 | PLC | Siemens | |

3 | PLC Expansion | Siemens | |

4 | Auxiliary Relay | OMRON | |

5 | Circuit Breaker | Schneider | |

6 | Contactor | Schneider | |

7 | Two Button rotary switch | Schneider | |

8 | Inching Button | Schneider | |

9 | Inching Button | Schneider | |

10 | Inching Button | Schneider | |

11 | Scram Button | Schneider | |

12 | Power Supply Switch | MW | |

13 | Radiator Fan&Square Shield(gray) | China | |

14 | Servo Motor | MITSUBISHI | |

15 | Servo Motor Drive | MITSUBISHI | |

16 | Cylinder | Air TAC | |

17 | Ultrasonic | China | |

18 | Solenoid Valve | Mindman | |

19 | Proximity Switch | OMORN | |

20 | Photoelectric Switch | OMORN | |

21 | Single Phase Motor | SONGGANG | |

22 | Air Switch | Schneider |

序列号 | 产品名称 | 产品图片 | 机器优势 |

1 | 伺服电机 |

| 我们使用三菱伺服电机,使机器工作稳定。口罩机行业品牌 |

2 | 触摸屏 |

| 西门子 PLC系统 |

3 | 电控箱 |

| 我们使用的是西门子 |

4 | 风扇 |

| 我们将风扇安装在超声波喇叭附近,降低喇叭温度,延长超声波寿命。 |

5 | 声波系统 |

| 一台点焊机器,2台超声波系统 |

6 | 口罩成品推送装置 |

| 我们机器上面使用气缸式口罩成品推送装置 |

7 | 独立输送带 |

| 我们安装口罩片材输送带 |